ChatGPT said: 10:9 Design Screen Printing Texas: packages explained

Wiki Article

Discover the Different Sorts Of Screen Printing Techniques for Your Next Project

Screen printing provides a diverse variety of techniques that can boost any type of creative project. From standard methods like serigraphy to contemporary advancements such as direct-to-garment printing, each technique has its one-of-a-kind advantages. Specialized choices, including environmentally friendly and metallic inks, present even much more opportunities. Understanding these strategies can considerably affect the final outcome. The obstacle lies in picking the most suitable method for particular requirements and preferred effects. What variables should one take into consideration?

The Fundamentals of Screen Printing

Screen printing might seem complex, it is fundamentally a straightforward procedure that includes moving ink with a mesh screen onto numerous surface areas. The method begins with the production of a stencil, which specifies the style to be printed. This stencil is affixed to a mesh screen, typically constructed from polyester or nylon. As soon as the stencil is in area, ink is put on the screen and pressed with the mesh using a squeegee, causing the preferred pattern being printed on the underlying product.Screen printing can be done on a broad range of substratums, including plastic, paper, and textile, making it a flexible choice for numerous jobs. The procedure enables for vibrant shades and elaborate layouts, making it prominent in sectors such as fashion, marketing, and art. Recognizing these fundamentals equips individuals with the fundamental knowledge needed to explore more innovative techniques in screen printing.

Standard Screen Printing Techniques

Traditional screen printing methods have actually been employed for centuries, maintaining the craftsmanship and creativity of this approach. This strategy makes use of a mesh screen to transfer ink onto a substratum, such as textile or paper, enabling lasting and lively styles. The process starts with developing a stencil, which blocks specific locations of the screen to regulate where the ink will certainly be applied.One preferred strategy is serigraphy, often used for restricted editions and artistic prints. An additional is making use of water-based inks, which are environmentally friendly and offer a soft feel on fabrics - 10:9 Design reviews. Furthermore, conventional methods can consist of hands-on printing, where artisans use ink with a squeegee, making certain precision and attention to information

These methods remain valued in the sector for their responsive high quality and the unique appearances they produce, interesting both developers and consumers who value the heritage of screen printing.

Digital Screen Printing Innovations

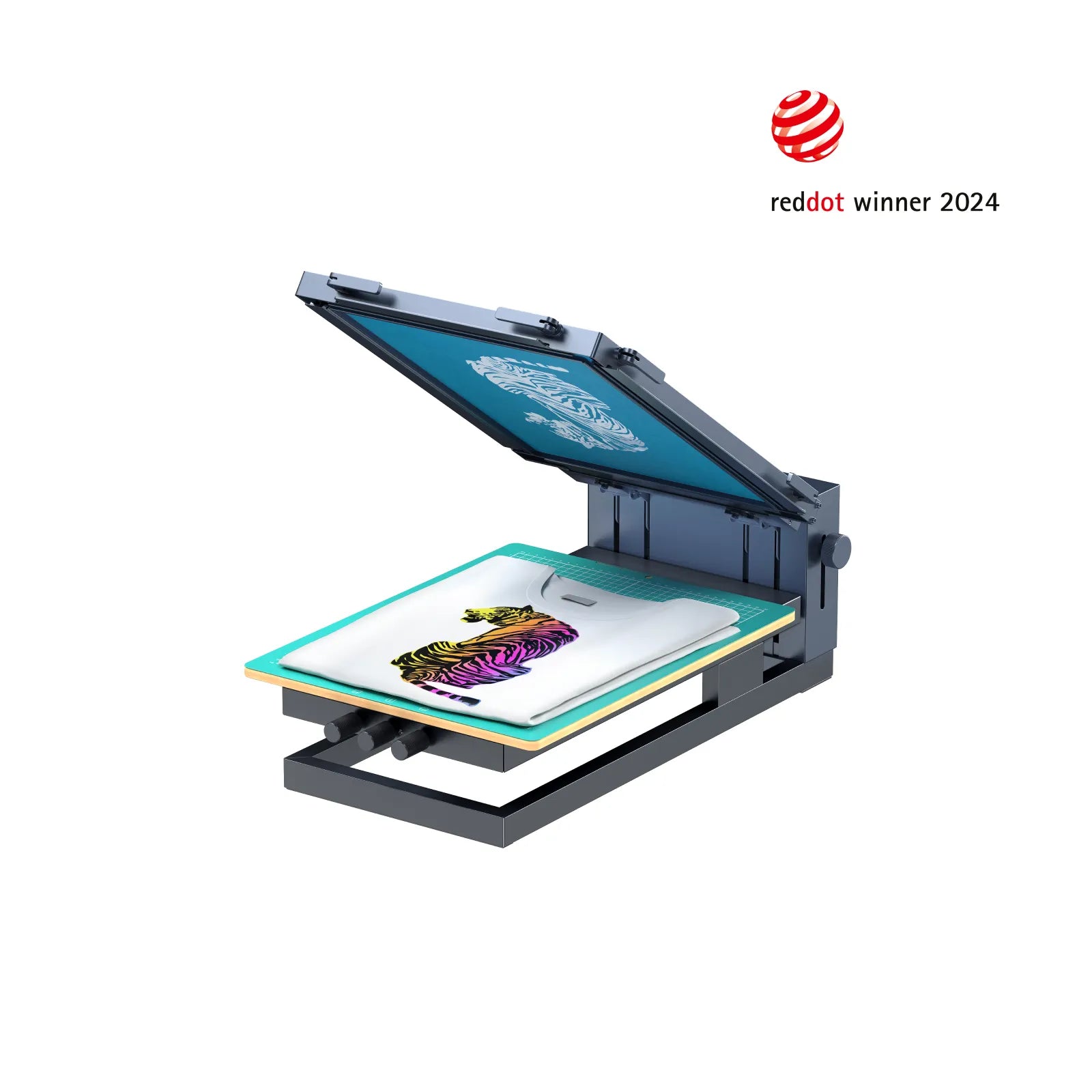

As the demand for faster manufacturing and personalization in the printing industry has actually surged, electronic screen printing developments have actually emerged as a game-changer. This technology mixes traditional screen printing approaches with digital procedures, allowing for quick prototyping and intricate layouts that were previously tough to achieve. One considerable development is the intro of direct-to-garment (DTG) printing, which helps with high-quality, full-color prints on different fabrics without the need for displays. In addition, developments in ink solutions have led to eco-friendly alternatives that maintain dynamic shades while reducing environmental effect. The usage of automated systems even more streamlines manufacturing, reducing labor prices and enhancing accuracy. These developments not just accommodate small batch orders and personalized layouts yet also enable for quicker turn-around times, making them excellent for companies focused on conference consumer needs in a fast-paced market. Digital screen printing, consequently, represents a crucial advancement in the domain of printing techniques.Specialty Screen Printing Methods

Checking out specialized screen printing techniques discloses a varied selection of strategies that press the borders of creativity and performance in the printing industry. Amongst these, glow-in-the-dark inks provide a distinct visual effect, making designs come alive in low-light conditions. Metal inks, recognized for their glittering coating, include a touch of deluxe to published materials. One more innovative method is discharge printing, which visit this website removes color from the textile rather of including ink, leading to a soft, vintage feel. High-density printing creates an elevated appearance on the surface area, improving tactile engagement. Additionally, water-based inks are obtaining popularity for their dynamic colors and reduced ecological influence. Each of these specialty techniques provides to details style requirements, allowing brands and musicians to create standout items that reverberate with their target markets. By leveraging these approaches, services can raise their screen printing jobs to new elevations, making sure memorable impacts.Eco-Friendly Screen Printing Options

Environment-friendly screen printing options are getting grip as the sector moves in the direction of sustainability. Lasting ink selections and making use of eco-friendly materials are key parts in lowering the ecological effect of the printing procedure. By taking on these practices, screen printers can add to a much more lasting future while keeping top notch results.Lasting Ink Options

Biodegradable Products Usage

As the screen printing sector evolves, the unification of naturally degradable products is ending up being significantly crucial for environmentally mindful practices. Makers and designers are currently discovering inks and substrates made from all-natural, renewable energies that decay much more successfully than conventional equivalents. These biodegradable choices lower plastic waste and reduce ecological influence, aligning with the growing need for sustainable items.

Common instances include water-based inks and organic cotton materials, both of which lessen harmful chemicals and promote eco-friendliness. Brands that adopt these materials often improve their market charm, drawing in customers who focus on sustainability. As awareness of ecological problems continues to increase, the shift towards eco-friendly products in screen printing is likely to obtain energy, fostering a greener sector requirement.

Selecting the Right Strategy for Your Project

How can one figure out one of the most suitable screen printing strategy for a particular task? The decision hinges on numerous aspects, including the product to be published on, the intricacy of the layout, and the preferred manufacturing quantity - 10:9 Design LLC Company. Direct-to-garment printing is excellent for detailed styles with numerous shades, while standard screen printing excels for larger runs of simpler graphics.

In addition, consideration of the end-use of the printed thing is vital. For outdoor applications, techniques that offer resilience and climate resistance, such as plastisol ink, may be preferred. On the other hand, environmentally-conscious projects may take advantage of naturally degradable materials or water-based inks.

Eventually, comprehending the job's unique requirements enables an enlightened choice, ensuring both aesthetic allure and practical durability. By evaluating style complexity, material compatibility, and production scale, one can effectively select the most appropriate screen printing method to fulfill their job's goals.

Often Asked Questions

What Is the History of Screen Printing?

Screen printing stemmed in ancient China around 1000 ADVERTISEMENT, progressing with Japan and Europe. By the 20th century, it ended up being popular in industrial art and style, reinventing exactly how layouts were generated and distributed worldwide.

How Do I Prepare Artwork for Screen Printing?

To prepare art work for screen printing, one need to ensure high resolution, make use of an appropriate shade mode, create separate layers for every shade, and transform text to describes, ensuring compatibility with the printing process and desired outcome.What Products Are Best for Screen Printing?

The most effective materials for screen printing include top notch inks, long lasting displays, and appropriate substrates like cotton, polyester, or blends. Furthermore, utilizing ideal emulsion and mops can enhance the printing process and final outcomes.Can I Screen Publish in your home?

Yes, screen printing in the house is possible. With the appropriate materials, arrangement, and techniques, individuals can create top notch like this prints. Nonetheless, cautious consideration of workspace and tools is crucial for effective results.

What Prevail Errors in Screen Printing?

Usual mistakes in screen printing consist of improper exposure times, insufficient ink uniformity, misalignment of displays, inadequate cleaning of materials, and neglecting to check prints. These errors can jeopardize the high quality and precision visit homepage of the last product.Screen printing may seem facility, it is basically a straightforward process that entails moving ink via a mesh screen onto various surface areas. As the demand for faster production and customization in the printing industry has actually risen, electronic screen printing developments have actually arised as a game-changer. Discovering specialized screen printing techniques exposes a diverse range of strategies that push the limits of imagination and functionality in the printing industry. The ideal materials for screen printing consist of top notch inks, durable screens, and suitable substratums like cotton, polyester, or blends (10:9 Design LLC Company). Usual errors in screen printing include inappropriate exposure times, inadequate ink uniformity, misalignment of screens, insufficient cleansing of products, and ignoring to check prints

Report this wiki page